Honda HR-V: Rocker Arm Assembly Removal and Installation

Removal

1. Cylinder Head Cover - Remove

2. Rocker Arm Assembly - Remove

- Loosen the locknuts and the adjusting screws (A).

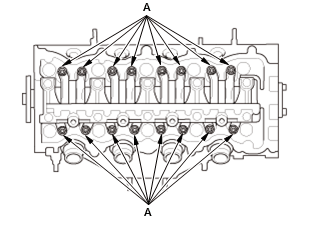

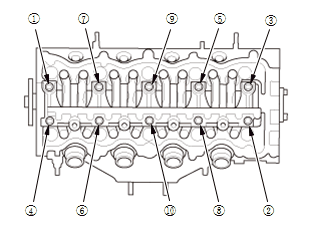

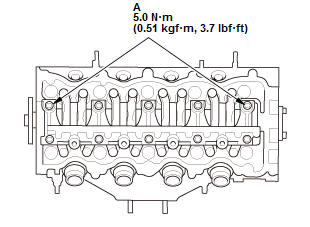

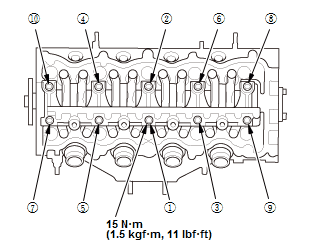

Fig. 32: Lost Motion Holder Bolt Removal Sequence

- Remove the lost motion holder bolts. To prevent damaging the lost motion holder and the rocker shaft

- loosen the bolts, in sequence, two turns at a time.

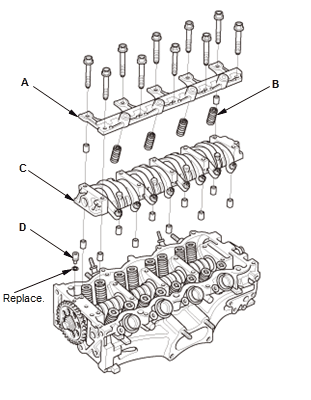

- Remove the lost motion holder (A) and the lost motion assemblies (B)

- Remove the rocker arm assembly (C)

- Remove the oil control orifice (D).

Installation

1. Rocker Arm Assembly - Reassemble

- If the rocker arm assembly is disassembled, reassemble the rocker arm assembly.

2. Rocker Arm Assembly - Install

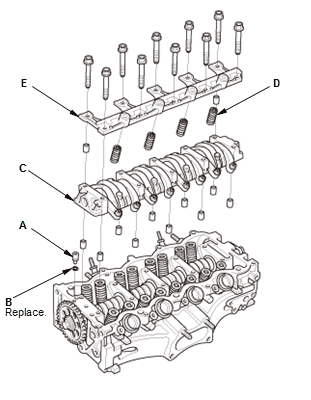

- Install the oil control orifice (A) with a new O-ring (B)

- Install the rocker arm assembly (C)

- Install the lost motion assembles (D) and the lost motion holder (E).

NOTE : Apply new engine oil to the lost motion assembly.

- Tighten the two lost motion holder bolts (A).

Fig. 33: Lost Motion Holder Tightening Sequence With Torque Specifications

- Tighten each bolts two turns at a time in sequence.

3. Valve Clearance - Adjust

4. Cylinder Head Cover - Install

ROCKER ARM OIL CONTROL VALVE REMOVAL AND INSTALLATION

Removal & Installation

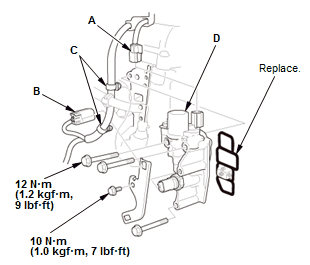

1. Rocker Arm Oil Control Valve - Remove

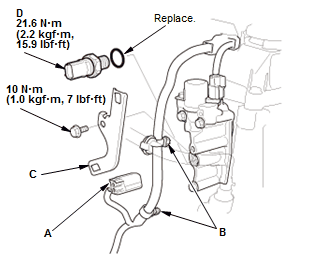

With rocker arm oil pressure switch or rocker arm oil pressure sensor

Without rocker arm oil pressure switch or rocker arm oil pressure sensor

- Disconnect the connector (A)

- With rocker arm oil pressure switch or rocker arm oil pressure sensor: Disconnect the connector (B)

- Remove the harness clamps (C)

- Remove the rocker arm oil control valve (D).

2. All Removed Parts - Install

- Install the parts in the reverse order of removal with a new O-ring.

ROCKER ARM OIL PRESSURE SWITCH REMOVAL AND INSTALLATION (KA/KC)

Removal & Installation

1. Rocker Arm Oil Pressure Switch - Remove

Fig. 34: Rocker Arm Oil Pressure Exploded View With Torque Specifications

- Disconnect the connector (A)

- Remove the harness clamps (B)

- Remove the bracket (C)

- Remove the rocker arm oil pressure switch (D).

2. All Removed Parts - Install

- Install the parts in the reverse order of removal with a new O-ring.

SECONDARY HO2S REMOVAL AND INSTALLATION (KA/KC)

Special Tools Required

O2 Sensor Socket Wrench Snap-on SWR2 or Snap-on YA8875, commercially available

Removal & Installation

1. Vehicle - Lift

- Raise and support the vehicle.

2. Secondary HO2S - Remove

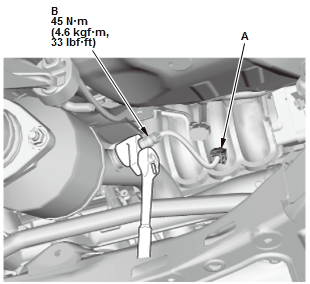

Fig. 35: Secondary HO2S With Torque Specifications

- Disconnect the connector (A)

- Remove secondary HO2S (B).

3. All Removed Parts - Install

- Install the parts in the reverse order of removal.