Honda HR-V: Cylinder Head Removal and Installation

Removal

NOTE:

- Use fender covers to avoid damaging painted surfaces.

- To avoid damaging the wiring and terminals, unplug the wiring connectors carefully while holding the connector portion.

- Connect the HDS to the DLC, and monitor ECT SENSOR 1. To avoid damaging the cylinder head, wait until the engine coolant temperature drops below 100 ºF (38 ºC) before loosening the cylinder head bolts.

- Mark all wiring and hoses to avoid misconnection. Also, be sure that they do not contact other wiring or hoses, or interfere with other parts.

1. Fuel Pressure - Relieve

NOTE: After relieving the fuel pressure, do not connect the quick-connect fitting.

2. Engine Coolant - Drain

3. Intake Manifold - Remove

4. Fuel Injector and Rail Assembly - Remove

5. Rocker Arm Oil Control Valve - Remove

6. Ignition Coil and Spark Plug - Remove

7. Connector (CMP Sensor) - Disconnect

8. Connector (ECT Sensor 1) - Disconnect - Refer to: ECT Sensor 1 Removal and Installation, or ECT Sensor 2 Removal and Installation

9. Connector (EGR Valve) - Disconnect

10. Positive Cable and Connector (Alternator) - Disconnect

NOTE: Remove the positive cable clamp at the same time.

11. Cylinder Head Cover Harness Holder - Move

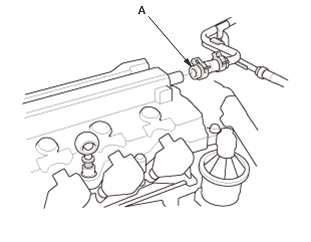

12. Breather Hose - Disconnect

- Disconnect the breather hose (A).

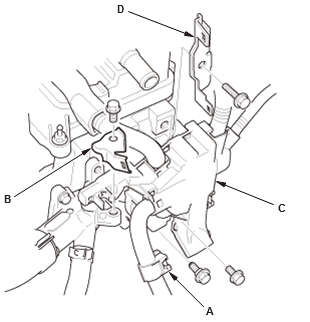

13. Harness Holder - Move

- Remove the harness clamp (A)

- Remove the bracket (B)

- Move the harness holder (C)

- Remove the bracket (D).

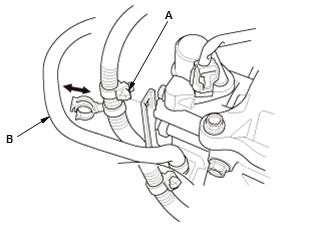

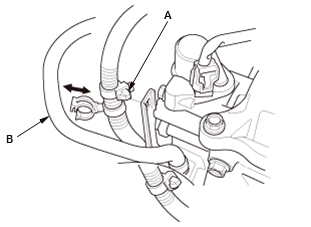

14. Harness Clamp and PCV Hose Clamp - Remove

- Remove the harness clamp (A) and the PCV hose clamp (B).

15. Water Outlet - Remove

16. Heater Outlet - Remove

17. Thermostat Housing - Remove

18. Exhaust Pipe A - Remove

19. Warm Up TWC - Remove (USA and Canada models) - Refer to: Warm Up TWC Removal and Installation (KA/KC), or Under-Floor TWC Removal and Installation (KA/KC)

20. Catalytic Converter - Remove (Mexico models) - Refer to: Warm Up TWC Removal and Installation (KA/KC), or Under-Floor TWC Removal and Installation (KA/KC)

21. Cylinder Head Cover - Remove

22. Cam Chain - Remove

23. Cylinder Head - Remove

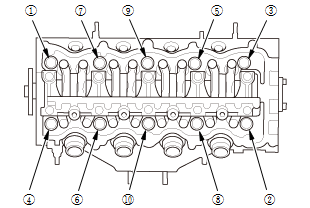

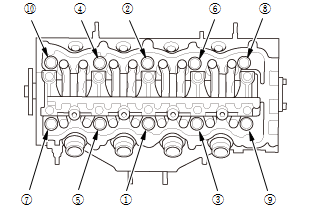

Fig. 3: Cylinder Head Bolts Loostening Sequence

- Remove the cylinder head bolts. To prevent warpage, loosen the bolts in sequence, 1/3 turn at a time; repeat the sequence until all bolts are loosened

- Remove the cylinder head

24. Heat Insulator - Remove

- Remove the heat insulator as needed

Installation

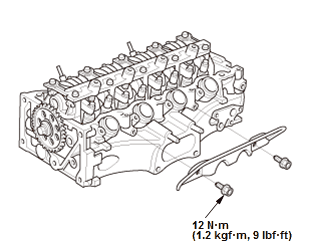

1. Heat Insulator - Install

Fig. 4: Heat Insulator With Torque Specifications

- If the heat insulator is removed, install the heat insulator.

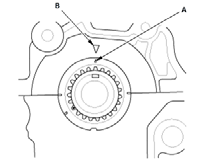

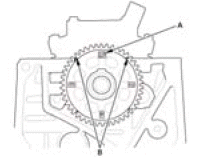

2. No. 1 Piston at Top Dead Center - Set

- Set the crankshaft to top dead center (TDC). Align the TDC mark (A) on the crankshaft sprocket with the pointer (B) on the engine block.

- Set the camshaft to TDC. The "UP" mark (A) on the camshaft sprocket should be at the top, and the TDC grooves (B) on the camshaft sprocket should aline up with the top edge of the cylinder head.

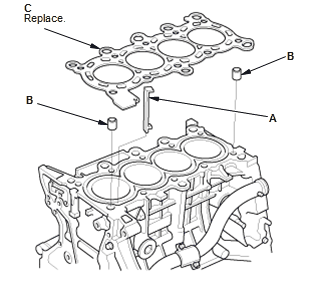

3. Cylinder Head - Install

- Clean the cylinder head and the engine block surfaces

- Install a new coolant separator (A) in the engine block whenever the engine block is replaced

- Install the dowel pins (B) and a new cylinder head gasket (C)

- Install the cylinder head on the engine block.

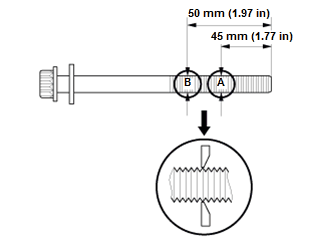

- Measure the diameter of each cylinder head bolt at point A and point B

- If either diameter is less than 10.6 mm (0.417 in), replace the cylinder head bolt

- Apply new engine oil to the threads and flange of all cylinder head bolts.

Fig. 5: Cylinder Head Bolts Tightening Sequence

- Torque the cylinder head bolts in sequence to 40 N.m (4.1 kgf.m, 30 lbf.ft), using a beam-type torque wrench. When using a preset click-type torque wrench, be sure to tighten slowly and do not overtighten. If a bolt makes any noise while you are torquing it, loosen the bolt and retighten it from the first step.

.png)

- After torquing, tighten all cylinder head bolts in two steps (90 º per step using the sequence shown in step 8). If you are using a new cylinder head bolt, tighten the bolt an extra 60 º.

NOTE: Remove the cylinder head bolt if you tightened it beyond the specified angle, and go back to step 5 of the procedure. Do not loosen it back to the specified angle.

4. Cam Chain - Install

5. Valve Clearance - Adjust

6. Cylinder Head Cover - Install

NOTE: Do not Install the cylinder head harness holder in this step.

7. Warm Up TWC - Install (USA and Canada models) - Refer to: Warm Up TWC Removal and Installation (KA/KC), or Under-Floor TWC Removal and Installation (KA/KC)

8. Catalytic Converter - Install (Mexico models) - Refer to: Warm Up TWC Removal and Installation (KA/KC), or Under-Floor TWC Removal and Installation (KA/KC)

9. Exhaust Pipe A - Install

10. Thermostat Housing - Install

11. Heater Outlet - Install

12. Water Outlet - Install

13. Harness Clamp and PCV Hose Clamp - Install

- Install the harness clamps (A) and the PCV hose clamp (B).

14. Harness Holder - Install

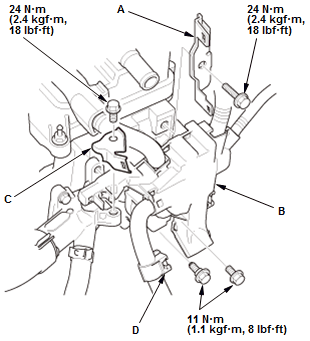

Fig. 6: Harness Holder With Torque Specifications

- Install the bracket (A) and the harness holder (B)

- Install the bracket (C) and the harness clamp (D).

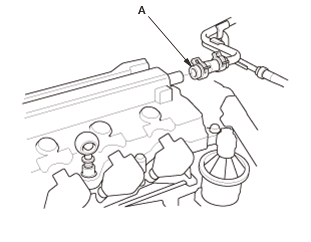

15. Breather Hose - Connect

- Connect the breather hose (A).

16. Cylinder Head Cover Harness Holder - Install

17. Positive Cable and Connector (Alternator) - Connect

NOTE: Install the positive cable clamp at the same time.

18. Connector (EGR Valve) - Connect

19. Connector (ECT Sensor 1) - Connect - Refer to: ECT Sensor 1 Removal and Installation, or ECT Sensor 2 Removal and Installation

20. Connector (CMP Sensor) - Connect

21. Spark Plug and Ignition Coil - Install

22. Rocker Arm Oil Control Valve - Install

23. Fuel Injector and Rail Assembly - Install

24. Intake Manifold - Install

25. Fuel Feed Hose (Fuel Rail Side) - Connect

26. Drive Belt Auto-Tensioner - Install

27. Fuel Leak - Inspect

- Turn the vehicle to the ON mode, but do not operate the starter. After the fuel pump runs for about 2 seconds, the fuel rail will be pressurized. Repeat this two or three times, then check for fuel leakage.

28. Engine Coolant - Refill/Air Bleed

29. Ignition Timing - Inspect

30. CKP Pattern - Clear/Learn