Honda HR-V: Engine Removal and Installation

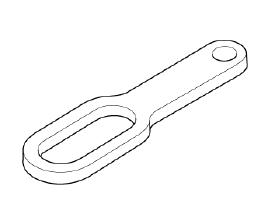

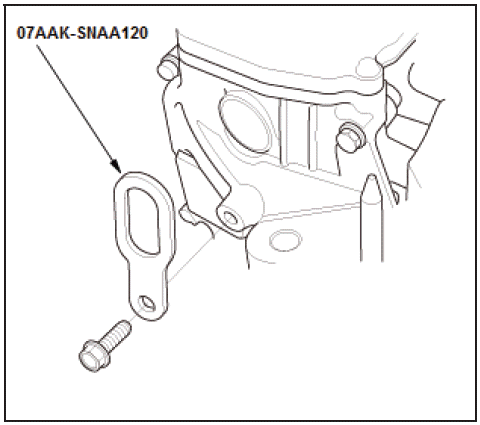

Special Tools Required

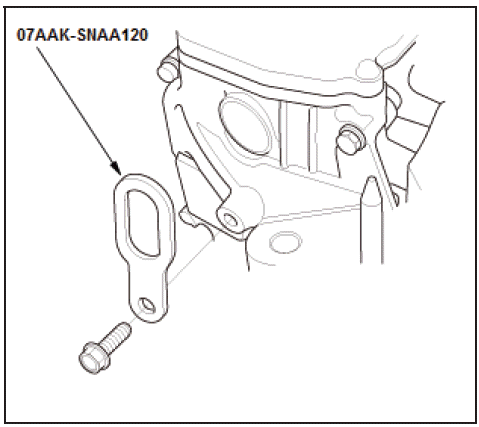

Universal Lifting Eyelet 07AAKSNAA120

Removal

NOTE:

- Use fender covers to avoid damaging painted surfaces.

- To avoid damaging the wiring and terminals, unplug the wiring connectors carefully while holding the connector portion.

- Mark all wiring and hoses to avoid misconnection. Also, be sure that they do not contact other wiring or hoses, or interfere with other parts.

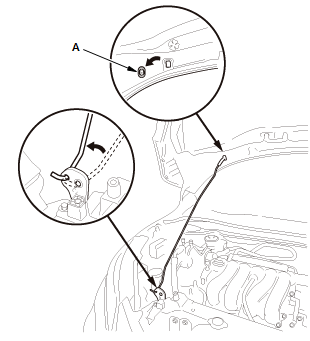

1. Hood - Wide Open

- Open the hood, and remove the plug cap (A).

- Change the hood support rod mounting position.

- Secure it with the hood support rod in the wide-open position.

2. Fuel Pressure - Relieve

NOTE: After relieving the fuel pressure, do not connect the quick-connect fitting.

3. 12 Volt Battery Terminal - Disconnect

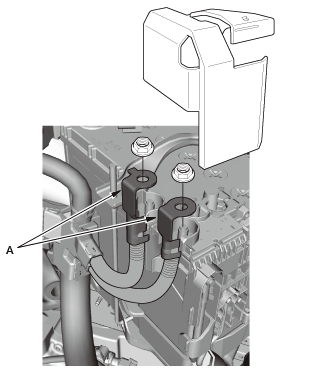

4. Positive Cable (12 Volt Battery Terminal Fuse Box) - Disconnect

- Remove the cover.

- Disconnect the positive cables (A).

5. 12 Volt Battery - Remove

6. Front Grille Cover - Remove

7. Air Cleaner - Remove

8. Intake Air Duct - Remove

9. Intake Air Resonator - Remove

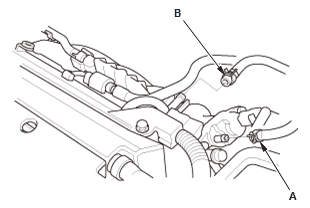

10. EVAP Canister Purge Hose and Brake Booster Vacuum Hose - Disconnect

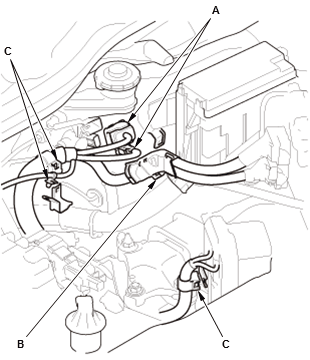

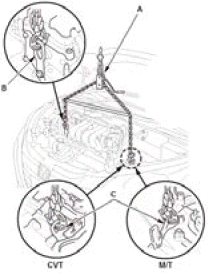

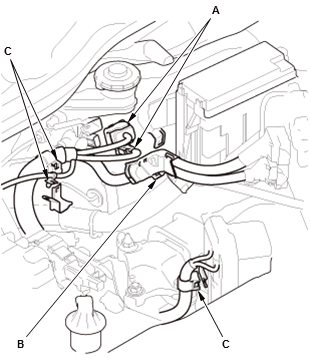

- Disconnect the EVAP canister purge hose (A) and the brake booster vacuum hose (B).

11. Connector (PCM) - Disconnect

12. Connector (Engine Wire Harness) - Disconnect

- Disconnect the connectors (A)

- Remove the harness holder clamp (B) and the harness clamps (C).

13. Change Wire Bracket - Remove (M/T)

14. Slave Cylinder - Move (M/T)

NOTE: Without disconnecting the clutch line.

15. Shift Cable (Transmission Side) - Disconnect (CVT)

16. Steering Joint - Disconnect

NOTE: Hold the steering wheel in the steering wheel holder tool.

17. Vehicle - Lift

- Raise and support the vehicle.

18. Front Wheel - Remove

19. Front Splash Shield and Engine Undercover (With Engine Undercover) - Remove

20. Drive Belt - Remove

21. A/C Pipe Clamp Bolt - Remove

22. Engine Coolant - Drain

23. Radiator - Remove

24. Engine Oil - Drain

25. Transmission Fluid - Drain

- Drain the transmission fluid:

- M/T

- CVT

26. Exhaust Pipe A - Remove

27. Front Stabilizer Link Ball Joint - Disconnect

28. Lower Arm Ball Joint - Disconnect

29. Tie-Rod End Ball Joint - Disconnect

30. Front Driveshaft - Remove

31. Propeller Shaft - Remove (AWD)

32. A/C Compressor - Move

NOTE:

- Do not disconnect the A/C hoses.

- Do not bend the A/C hoses excessively.

- Disconnect the connector at the same time.

- Hang the A/C compressor with a wire tie.

33. Torque Rod - Remove

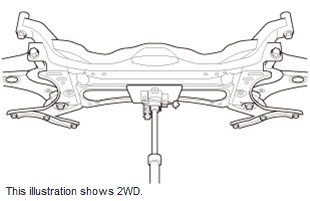

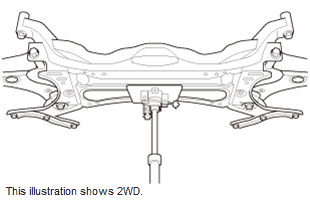

34. Front Subframe - Support

- Support the front subframe with a transmission jack.

35. Front Subframe - Remove

36. Vehicle - Lift

- Lower the vehicle.

37.Heater Hose - Disconnect

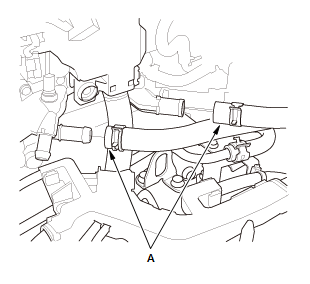

- Disconnect the heater hoses (A).

38. Engine - Support

- Lift and support the engine with a jack and a wood block under the oil pan.

39. Side Engine Mount - Remove

NOTE: Do not remove the bolt that tighten the side engine mount and the side engine mount bracket.

40. Universal Lifting Eyelet - Install

41. Chain Hoist - Install

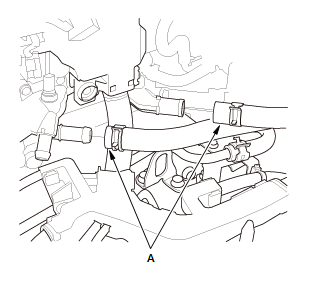

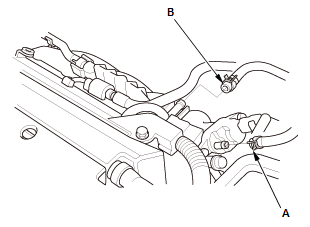

- Attach the chain hoist (A) to the universal lifting eyelet (B) and the transmission hanger (C), then lift the engine/transmission until it is securely supported by the chain hoist.

42. Transmission Mount Bracket Mounting Bolt and Nut - Remove

43. Engine - Remove

- Check that the engine/transmission is completely free of the vacuum hoses, the fuel hoses, the coolant hoses, and the electrical wiring.

- Slowly lower the engine/transmission about 150 mm (5.91 in). Check once again that all the hoses and the electrical wiring are disconnected and free from the engine/transmission, then lower it all the way and support it.

- Remove the chain hoist from the engine/transmission.

- Raise the vehicle, and remove the engine/transmission from under the vehicle.

Installation

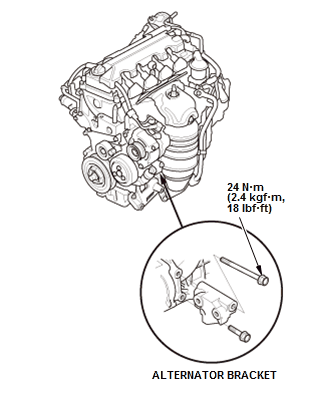

1. Accessory Bracket - Install

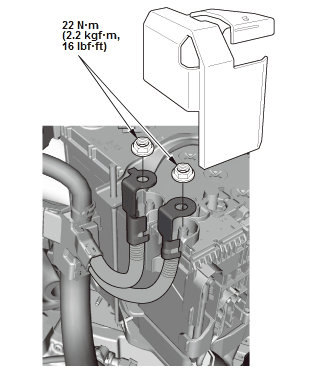

Fig. 22: Alternator Bracket Location With Torque Specifications

- If the alternator bracket is removed, install the alternator bracket.

- If the A/C compressor bracket is removed, install the A/C compressor bracket.

- If the torque rod bracket is removed, install the torque rod bracket.

NOTE: Always use new bolts.

(2WD)

2. Universal Lifting Eyelet - Install

3. Engine - Install

- Attach the chain hoist (A) to the universal lifting eyelet (B) and the transmission hanger (C), then lift the engine/transmission until it is securely supported by the chain hoist.

- Position the engine/transmission under the vehicle. Be sure that they

are properly aligned.

Carefully lower the vehicle until the engine/transmission are properly positioned in the engine compartment. Make sure the vehicle is not resting on any part of the engine/transmission.

Support the engine/transmission with the chain hoist and carefully raise the engine/transmission into place.

4. Transmission Mount Bracket Mounting Bolt and Nut - Loosely Install

NOTE: Always use new bolts and new nuts.

5. Engine - Support

- Lift and support the engine with a jack and a wood block under the oil pan.

6. Chain Hoist and Universal Lifting Eyelet - Remove

7. Side Engine Mount - Loosely Install

NOTE:

- Always use new bolts and new nuts.

- Connect the ground cable at the same time.

8. Vehicle - Lift

- Raise the vehicle.

9. Front Subframe - Support

- Support the front subframe with a transmission jack.

10.Front Subframe - Install

11.Torque Rod - Loosely Install

NOTE: Always use new bolts.

12.Vehicle - Lift

- Lower the vehicle.

13.All Engine Mount Mounting Bolt and Nut - Tighten

14.Vehicle - Lift

- Raise the vehicle.

15.A/C Compressor - Install

NOTE: Connect the connector at the same time.

16.Propeller Shaft - Install (AWD)

17.Front Driveshaft - Install

18.Tie-Rod End Ball Joint - Connect

19.Lower Arm Ball Joint - Connect

20.Front Stabilizer Link Ball Joint - Connect

21.Exhaust Pipe A - Install

22.Drive Belt - Install

23.A/C Pipe Clamp Bolt - Install

24.Radiator - Install

25.Front Splash Shield and Engine Undercover (With Engine Undercover) - Install

26.Front Wheel - Install

27.Vehicle - Lift

- Lower the vehicle.

28.Steering Joint - Connect

29.Heater Hose - Connect

- Connect the heater hoses (A).

30.Slave Cylinder - Install (M/T)

31.Change Wire Bracket - Install (M/T)

32.Shift Cable (Transmission Side) - Connect (CVT)

33.Fuel Feed Hose (Fuel Rail Side) - Connect

34.Connector (Engine Wire Harness) - Connect

- Connect the connectors (A)

- Install the harness holder clamp (B) and the harness clamps (C).

35.Connector (PCM) - Connect

36.EVAP Canister Purge Hose and Brake Booster Vacuum Hose - Connect

- Connect the EVAP canister purge hose (A) and the brake booster vacuum hose (B).

37.Intake Air Resonator - Install

38.Intake Air Duct - Install

39.Air Cleaner and Air Intake Duct - Install

40.Front Grille Cover - Install

41.12 Volt Battery - Install

NOTE: Do not connect the 12 Volt battery negative terminal in this step.

42.Positive Cable (12 Volt Battery Terminal Fuse Box) - Connect

Fig. 23: Battery Cables At Terminal Fuse Box With Torque Specifications

- Connect the positive cables

- Install the cover.

43.12 Volt Battery Terminal - Connect

44.Fuel Leak - Inspect

- Turn the vehicle to the ON mode, but do not operate the starter. After the fuel pump runs for about 2 seconds, the fuel rail will be pressurized. Repeat this two or three times, then check for fuel leakage.

45.Engine Oil - Refill

46.Transmission Fluid - Refill

- Refill the transmission fluid:

- M/T

- CVT

47.Engine Coolant - Refill/Air Bleed

48.Transmission Gear - Check

- M/T: Check that the transmission shifts into all gears smoothly

- CVT: Move the shift lever to each gear, and verify that the A/T gear position indicator follows the transmission range switch.

49.PCM - Reset

50.CKP Pattern - Clear/Learn

51.Idle Speed - Inspect

52.Ignitiion Timing - Inspect

53.Wheel Alignment - Check

54.VSA Sensor Neutral Position - Memorization