Honda HR-V: Intermediate Shaft Disassembly and Reassembly

Honda HR-V (2015-2021) Service Manual / Driveline & Axles / Driveshafts - Overhaul, Inspection & Adjustment / Disassembly and Reassembly / Intermediate Shaft Disassembly and Reassembly

Special Tools Required

Half Shaft Base 07NAF-SR30101

Oil Seal Driver, 44.5 mm 07947-SB00100

Driver Handle, 15 x 135L 07749-0010000

Bearing Driver Attachment, 52 x 55 mm 07746-0010400

Oil Seal Driver, 65 mm 07JAD-PL90100

Bearing Driver Attachment, 35 mm I.D.

07746-0030400

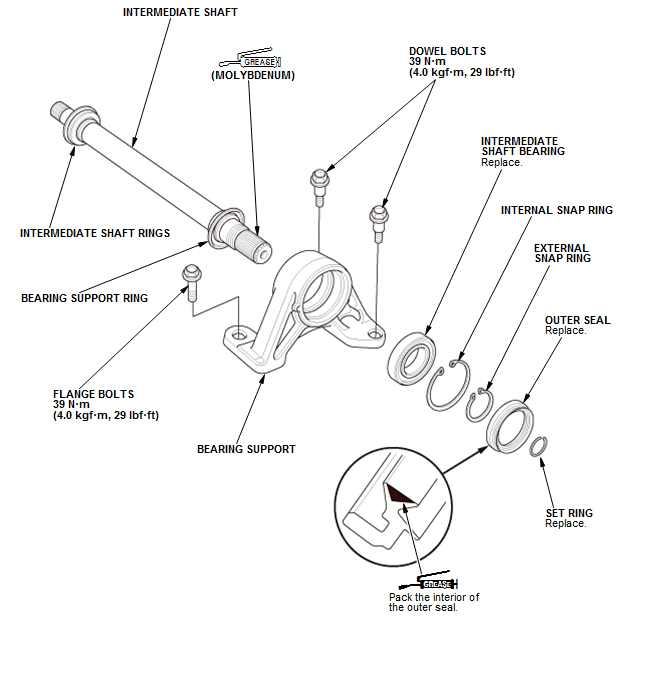

Exploded View

1. Intermediate Shaft - Exploded View

Fig. 2: Exploded View Of Intermediate Shaft

Disassembly

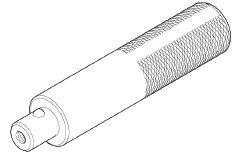

1. Intermediate Shaft - Remove

- Remove the outer seal (A)

- Remove the external snap ring (B).

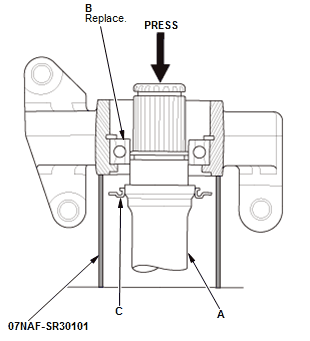

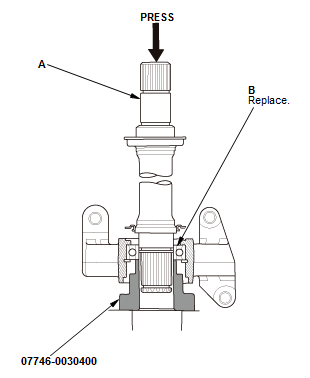

- Press the intermediate shaft (A) out of the intermediate shaft bearing

(B) using the half shaft base and a press.

NOTE: Be careful not to damage the bearing support ring (C) on the intermediate shaft during disassembly.

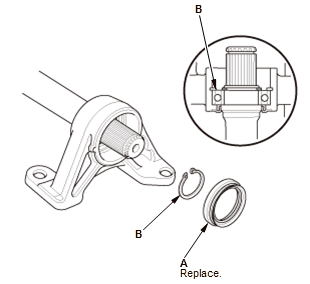

2. Intermediate Shaft Bearing - Remove

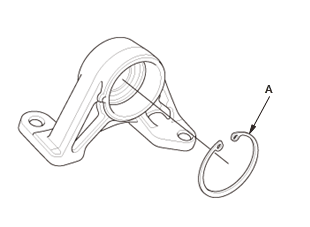

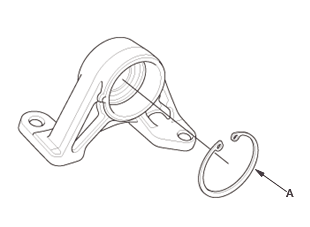

- Remove the internal snap ring (A).

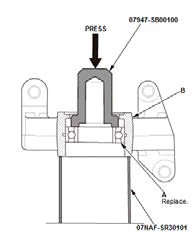

- Press the intermediate shaft bearing (A) out of the bearing support (B) using the half shaft base, the 65 mm oil seal driver attachment, and a press.

Reassembly

Refer to the Exploded View as needed during this procedure.

1. Intermediate Shaft Bearing - Install

- Clean the disassembled parts with solvent.

NOTE: Do not wash the rubber parts with solvent.

- Dry the disassembled parts with compressed air.

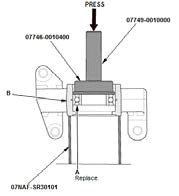

- Press a new intermediate shaft bearing (A) into the bearing support (B) using the 52 x 55 mm bearing driver attachment, the 15 x 135L driver handle, and a press.

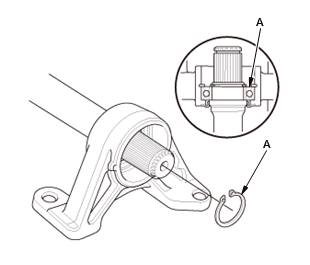

- Install the internal snap ring (A).

2. Intermediate Shaft - Install

- Press the intermediate shaft (A) into the shaft bearing (B) using a press.

- Install the external snap ring (A).

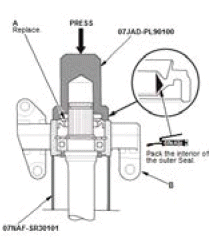

- Install a new outer seal (A) into the bearing support (B) using the 65 mm oil seal driver, the half shaft base, and a press. Press in the seal until it is even with the surface of the bearing support.

READ NEXT:

Rear Driveshaft Disassembly and Reassembly (AWD)

Rear Driveshaft Disassembly and Reassembly (AWD)

Special Tools Required

Slide Hammer 5/8"-18 UNF, commercially available

Threaded Adapter, 22 x 1.5 mm 07XAC-001010A

Boot Band Clamp Tool Kent-Moore J-35910 or

equivalent, commercially available

CV

SEE MORE:

DTC Troubleshooting B2840-13, B2841-13: SRS Unit Connector Not

Properly Installed

DTC Troubleshooting B2840-13, B2841-13: SRS Unit Connector Not

Properly Installed

NOTE:

Before doing this troubleshooting procedure, find out if the vehicle was

in a collision. If so, verify

that all the required components were replaced with new components of the

correct part number,

and that they were properly installed.

Before doing this troubleshooting procedure, rev

Description

Description

AUTOMATIC DIMMING MIRRORS SYSTEM DESCRIPTION - CONTROL/FUNCTION

When the automatic dimming off button is turned ON, the control unit receives

signals from each sensor. Based

on the difference between the two lux levels (the light outside the vehicle and

the light from the headlights of

the other v

© 2019-2026 Copyright www.hohrv2.com