Honda HR-V: Final Drive Shaft Disassembly and Reassembly (CVT)

Honda HR-V (2015-2021) Service Manual / Transmission / Continuously Variable Transmission (CVT) - Testing & Troubleshooting / Disassembly and Reassembly / Final Drive Shaft Disassembly and Reassembly (CVT)

Special Tools Required

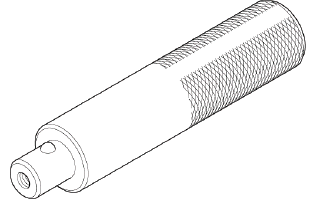

Driver Handle, 15 x 135L 07749-0010000

Attachment, 45 mm 07947-6890300

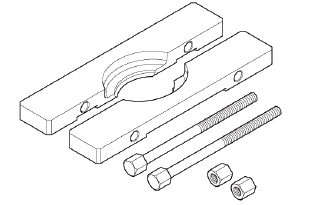

Bearing Separator 07KAF-PS30200

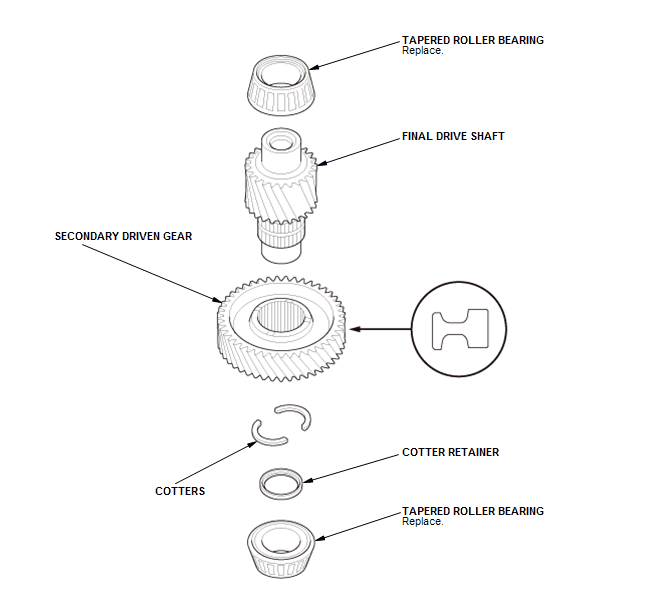

Exploded View

1. Final Drive Shaft - Exploded View

Disassembly

NOTE: The tapered roller bearing and the tapered roller bearing outer race should be replaced as a set.

1. Final Drive Shaft Tapered Roller Bearing - Remove

Transmission housing side

Torque converter housing side

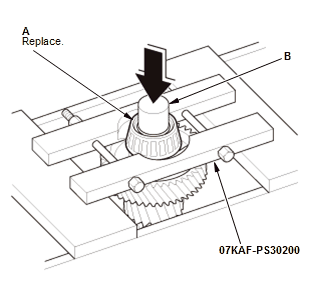

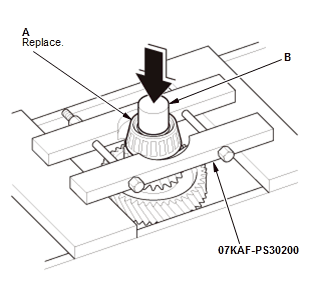

- Remove the tapered roller bearings (A) using the bearing separator and a press (B).

2. Secondary Driven Gear - Remove

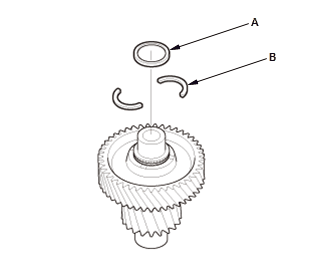

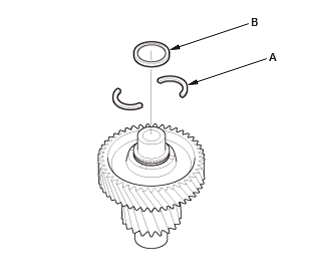

- Remove the cotter retainer (A) and the cotters (B).

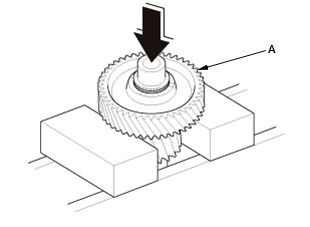

- Remove the secondary driven gear (A) using a press.

Reassembly

NOTE:

- The tapered roller bearing and the tapered roller bearing outer race should be replaced as a set.

- Adjust the tapered roller bearing preload after replacing the tapered roller bearing and the tapered roller bearing outer race.

- Apply a light coat of clean transmission fluid on all parts before installation.

1. Secondary Driven Gear - Install

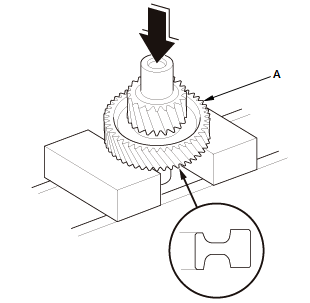

- Install the secondary driven gear (A) until it bottoms using a press as shown.

- Install the cotters (A) and the cotter retainer (B).

2. Final Drive Shaft Tapered Roller Bearing - Install

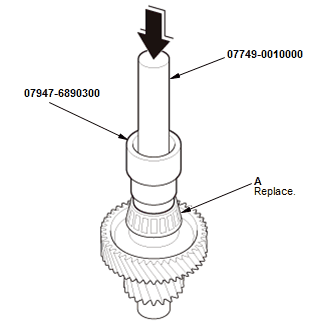

Transmission housing side

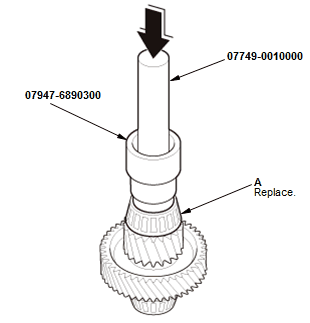

Torque converter housing side

- Install the tapered roller bearings (A) until they bottom using the 15 x 135L driver handle, the 45 mm attachment, and a press.

READ NEXT:

Shift Lever Disassembly and Reassembly (CVT)

Shift Lever Disassembly and Reassembly (CVT)

Exploded View

1. Shift Lever Assembly - Exploded View

NOTE: Do not wipe off the special grease applied to the area of the shift

lever marked with an asterisk (*).

Fig. 55: Exploded View Of Shift Lev

Transfer Assembly Disassembly and Reassembly (CVT)

Transfer Assembly Disassembly and Reassembly (CVT)

Special Tools Required

Oil Seal Driver Attachment, 58 mm 07JAD-PH80101

Holder, Companion 07PAB-0020000

Driver, 32.5 mm 070AD-SAA0100

Driver Handle, 15 x 135L 07749-0010000

Exploded View

1. Transfe

Component Location Index

Component Location Index

A/T GEAR POSITION INDICATOR COMPONENT LOCATION INDEX (CVT)

Without paddle shifter

With paddle shifter

A/T INTERLOCK SYSTEM COMPONENT LOCATION INDEX (CVT)

CVT DIFFERENTIAL COMPONENT LOCATION INDEX

SEE MORE:

Starter System Circuit Troubleshooting (Without Keyless Access System)

Starter System Circuit Troubleshooting (Without Keyless Access System)

NOTE:

Air temperature must be between 59-100ºF (15-38ºC) during this

procedure.

After the inspection, you must reset the PCM. Otherwise, the PCM will

continue to stop the fuel

injectors from operating.

The 12 volt battery must be in good condition and fully charged.

1. Starting syste

Transfer Assembly Disassembly and Reassembly (CVT)

Transfer Assembly Disassembly and Reassembly (CVT)

Special Tools Required

Oil Seal Driver Attachment, 58 mm 07JAD-PH80101

Holder, Companion 07PAB-0020000

Driver, 32.5 mm 070AD-SAA0100

Driver Handle, 15 x 135L 07749-0010000

Exploded View

1. Transfer Assembly - Exploded View

Fig. 56: Exploded View Of Transfer Assembly With Torque Specifications

D

© 2019-2026 Copyright www.hohrv2.com