Honda HR-V: Mainshaft Disassembly, Reassembly, and Inspection (M/T)

Special Tools Required

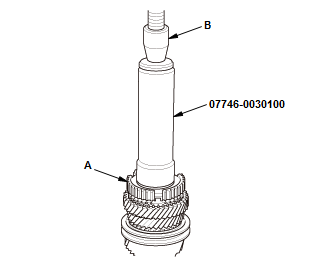

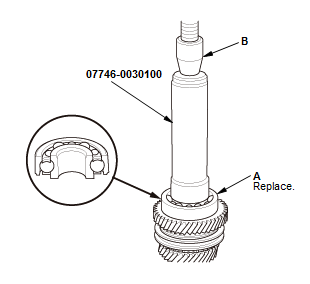

Driver Handle, 40 mm I.D. 07746-0030100

.png)

Driver, 30 mm I.D. 07946-MB00000

.png)

Disassembly

NOTE: Refer to the Exploded View as needed during this procedure.

1. Mainshaft - Disassemble

.png)

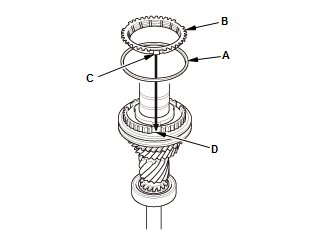

- Support 6th gear (A) on steel blocks, and press the mainshaft out of the

angular ball

bearing (B) and 6th gear using an attachment (C) and a press (D).

NOTE: Do not use a jaw-type puller; it can damage the gear teeth.

.png)

- Support 5th gear (A) on steel blocks, and press the mainshaft out of the

5th/6th

synchro hub (B) and 5th gear using an attachment (C) and a press (D).

NOTE: Do not use a jaw-type puller; it can damage the gear teeth.

.png)

- Support 3rd gear (A) on steel blocks, and press the mainshaft out of the

3rd/4th

synchro hub (B) and 3rd gear using an attachment (C) and a press (D).

NOTE: Do not use a jaw-type puller; it can damage the gear teeth.

.png)

- Support the angular ball bearing (A) on steel blocks, and press out the mainshaft using an attachment (B) and a press (C).

Inspection

1. Mainshaft - Inspect

Standard:

- Ball Bearing Contact Area (Transmission Housing Side): 30.984-31.000 mm (1.21984-1.22047 in)

- 6th Gear Distance Collar Contact Area: 32.984-33.000 mm (1.29858-1.29921 in)

- 4th/5th Gear Distance Collar Contact Area: 35.984-36.000 mm (1.41669-1.41732 in)

- Needle Bearing Contact Area: 41.984-42.000 mm (1.65291-1.65354 in)

- Ball Bearing Contact Area (Clutch Housing Side):

28.002-28.015 mm (1.10244-1.10295 in)

Crankshaft Pilot Bushing Contact Area: 20.80-20.85 mm (0.8189-0.8209 in)

Service Limit:

- 30.984 mm (1.21984 in)

- 32.984 mm (1.29858 in)

- 35.984 mm (1.41669 in)

- 41.984 mm (1.65291 in)

- 28.002 mm (1.10244 in)

- 20.80 mm (0.8189 in)

.png)

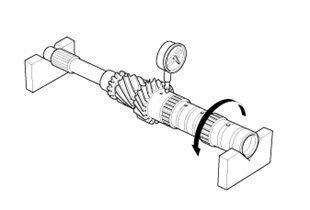

- Inspect the runout by supporting both ends of the mainshaft. Then rotate the mainshaft two complete turns while measuring with a dial gauge. If the runout exceeds the standard, replace the mainshaft.

Standard: 0.02 mm max.

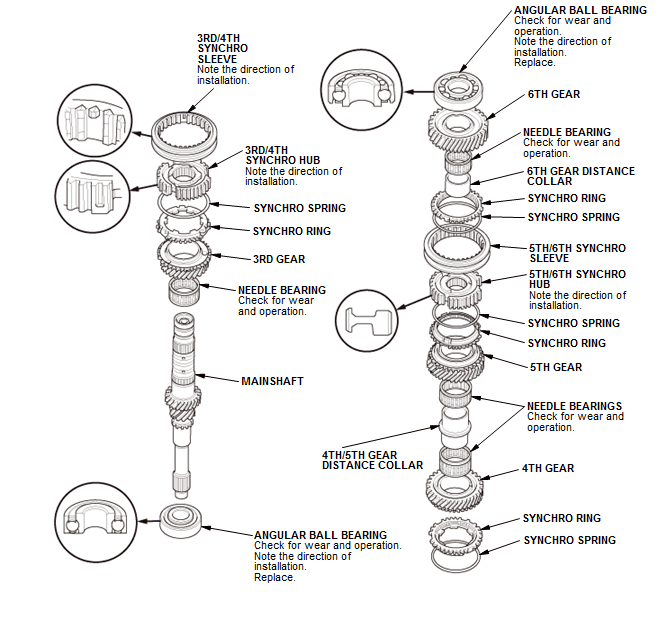

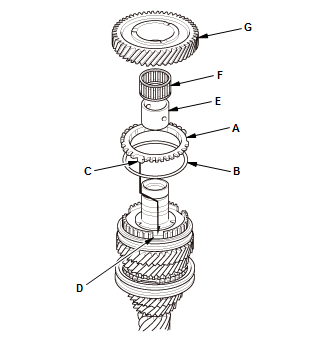

Exploded View

1. Mainshaft - Exploded View

Fig. 28: Exploded View Of Mainshaft

Reassembly

NOTE: Refer to the Exploded View as needed during this procedure.

1. Mainshaft - Reassemble

- Clean all parts in solvent, dry them, and apply MTF to all contact surfaces

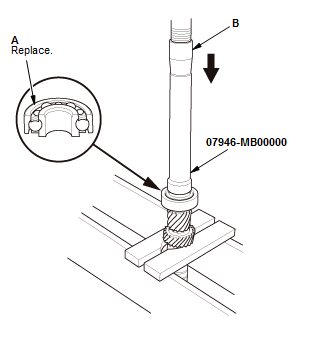

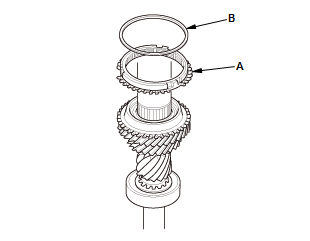

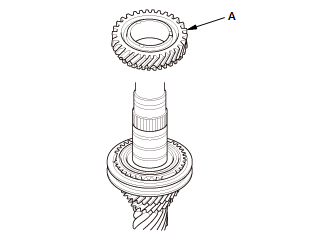

- Press in a new angular ball bearing (A) using the 30 mm I.D. driver and

a press (B).

NOTE: Check the ball bearing install direction.

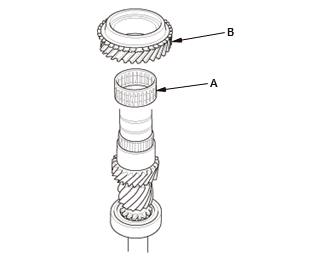

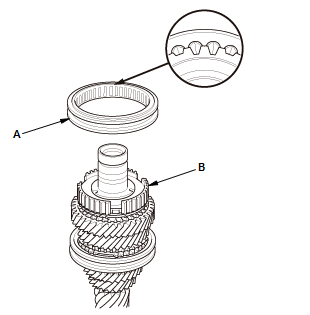

- Install the needle bearing (A)

- Install 3rd gear (B).

- Install the synchro ring (A) and synchro spring (B).

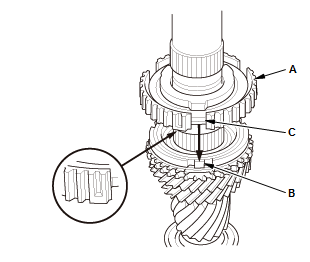

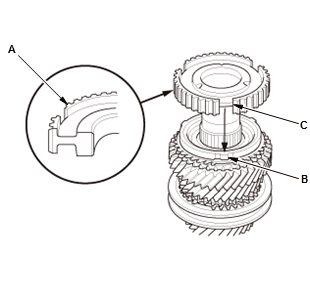

- Install the 3rd/4th synchro hub (A) by aligning the synchro ring fingers

(B) with the

grooves (C) in the 3rd/4th synchro hub.

NOTE: Make sure to install the 3rd/4th synchro hub in the direction shown.

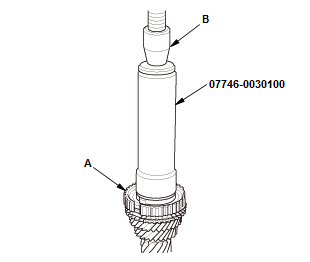

- Press on the 3rd/4th synchro hub (A) using the 40 mm I.D. driver handle and a press (B).

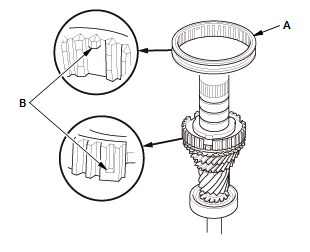

- Install the 3rd/4th synchro sleeve (A) by aligning the stops (B) of the 3rd/4th synchro sleeve and the 3rd/4th synchro hub

- Check the operation of the 3rd/4th synchro hub set.

- Install the synchro spring (A)

- Install the synchro ring (B) by aligning the synchro ring fingers (C) with the grooves in 3rd/4th synchro hub (D).

- Install the 4th gear (A).

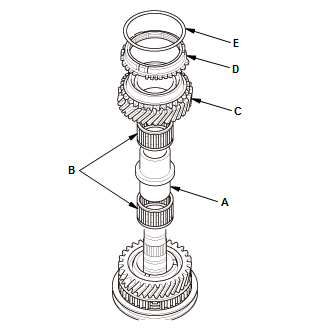

- Install the 4th/5th gear distance collar (A) with the needle bearings (B) and 5th gear (C)

- Install the synchro ring (D) with the synchro spring (E) onto 5th gear.

- Install the 5th/6th synchro hub (A) by aligning the synchro ring fingers (B) with the grooves (C) in the 5th/6th synchro hub.

- Press on the 5th/6th synchro hub (A) using the 40 mm I.D. driver handle and a press (B).

- Install the 5th/6th synchro sleeve (A) by aligning the slots of the

5th/6th synchro

sleeve and the 5th/6th synchro hub (B).

NOTE: Make sure to align the slots in the 5th/6th synchro sleeve as shown.

- Check the operation of the 5th/6th synchro hub set.

- Install the synchro ring (A) with the synchro spring (B) by aligning the synchro ring fingers (C) with the grooves (D) in the 5th/6th synchro hub

- Install the 6th gear distance collar (E) with the needle bearing (F) and 6th gear (G).

- Press on a new angular ball bearing (A) using the 40 mm I.D. driver

handle and a

press (B).

NOTE: Check the ball bearing install direction.